Back in 2011, we here at Dyson Medic reported on the Demise of DC01 Spare Parts.

We highlighted that Dyson had pulled the plug on all spare parts supply for the DC01 and DC02 altogether, and indeed in some countries, we know they sent what was left of the spares for them for destruction at specialist companies.

The issue Dyson faced was similar to what Volvo once had: Some models were engineered so well that owners were inclined to simply have them repaired for many years. So the way to kill off the old ones is to cease spare part supply and they slowly die.

The marketing idea behind this is that people will then dash out and buy a new model Dyson ball, but we don’t think that many of them actually do. What many will do after a DC01 performed well enough for over fifteen years is eschew a new machine at over £300 and instead buy a reconditioned Dyson for less than half that.

But the DIY enthusiast, and certainly the collectors, will want to keep on repairing their trusty old DC01′s.

So lets look at the position of spare part supply in 2014, three years after Dyson pulled the plug.

What isn’t available any more?

Some things are now very, very rare and in short supply. If you find them used, you will pay a premium.

DA001 fixed soleplates fall into this category. These date from the very earliest of Dysons before they became swivelling soleplates. If you want further explanation on those, you can find it here: Dyson DC01 Variants: Fixed and Swivelling Sole Plates — The Differences.

Likewise, front bumpers for those early machines are like gold dust now. Expect to pay £25 for a mint one.

New motors are no longer available (although I know of an Ametek one). Used motors are in short supply in good condition; the YDK types being the rarer. YDK armatures are also no longer available. Ametek carbon brushes are no longer available either.

Good red De Stijl wands are in very short supply in the used market. Most have damaged tool holders or hairline cracks in the side of them. At the time of writing, new after-market grey wands are still available. But I am not sure for how long.

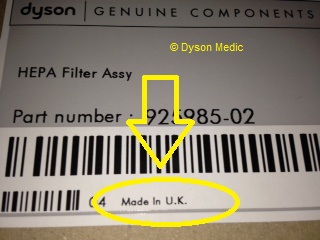

Genuine washable filters are long obsolete, but if you know where to look, you can still find them if you want them.

What is still in plentiful supply?

New, nothing except after-market filters, belts, back hoses and tools. However, that leaves used spare parts.

Cleaner heads (used) are still around, both types. Chassis (duct) assemblies are still plentiful used.

Filters and tools are still around. As are used cyclone units and bins. Wheels and axles are also quite plentiful.

New after-market grey wands and brushrolls are still about, as are new yellow front bumpers, but the only UK trade supplier of these has just doubled the price, which tells us they are coming to an end and they are milking the last few quid from the stock that is left. Accordingly, prices have doubled everywhere overnight this week for those.

I expect wands and brushrolls will go the same way (double in price) in the near future as it is doubtful that anyone will commision further production runs of them when current supplies are gone. And only one UK after-market company supplies them now.

Synopsis.

The DC01 will be around for a while yet. Although parts supply will continue to diminish.

What is interesting though is that collectors, enthusiasts and Dyson specialists are now starting to take an interest in them. You can read here the story of how Manchester Vacs recently restored a DC01 De Stijl to a superb standard using many new parts not generally available any more: >>Building a pristine Dyson DC01 to store<<.

There is a lot of discussion on that topic about the availability of DC01 spares as well. As well as lots of interesting photos for the Dyson anoraks among us.

You will find more on the DC01 at our original Dyson Medic site in the DC01 section: The original Dyson Medic DC01 Guides.

If you have any thoughts or opinions on the DC01, you are welcome to use the comment box below.